VIC-20 Power Plug

The older VIC-20 models have two-prong power plugs, which are not available anymore. While the American model can be adapted with a mains connector (C7 type, I think - never plug that into the electric outlet!), the European models have a different type of two prong connector.

VIC-20 side cover with the Euro 9VAC connector

First, I was measuring the pins in order to find some suitable crimp terminals. The diameter is about 3.3mm, so a 3.5mm bullet connector was assumed to work.

First test of the 3.5mm female bullet connector crimp terminals

The said crimp terminals seem to fit well enough. Real life testing will have to prove it, though.

The next step was taking all measures of the connector with a caliper and a radius gauge and drawing the connector base, which should fit inside the connector.

Fitting the first attempt of the connector base with the power connector

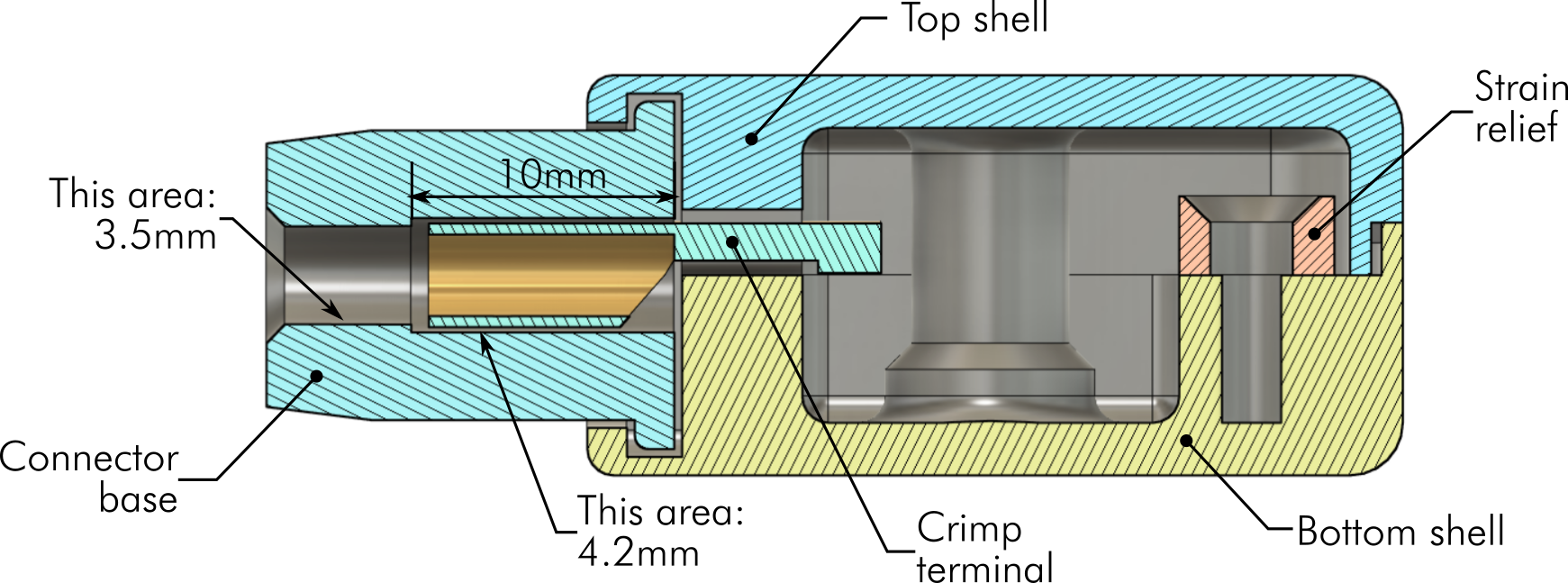

This worked out fine. The 3D-printed connector cannot look the same like the original connector, because the original was injection molded with a flexible plastic, the crimp terminals are held by the injection molding compound, while the 3D-printed connector has to consist of several parts to hold the crimp terminals in place.

Those are connector base, bottom and top shell and a strain relief, which is clamping the cable to the bottom shell. The crimp terminals are held by the connector base and both shells of the body.

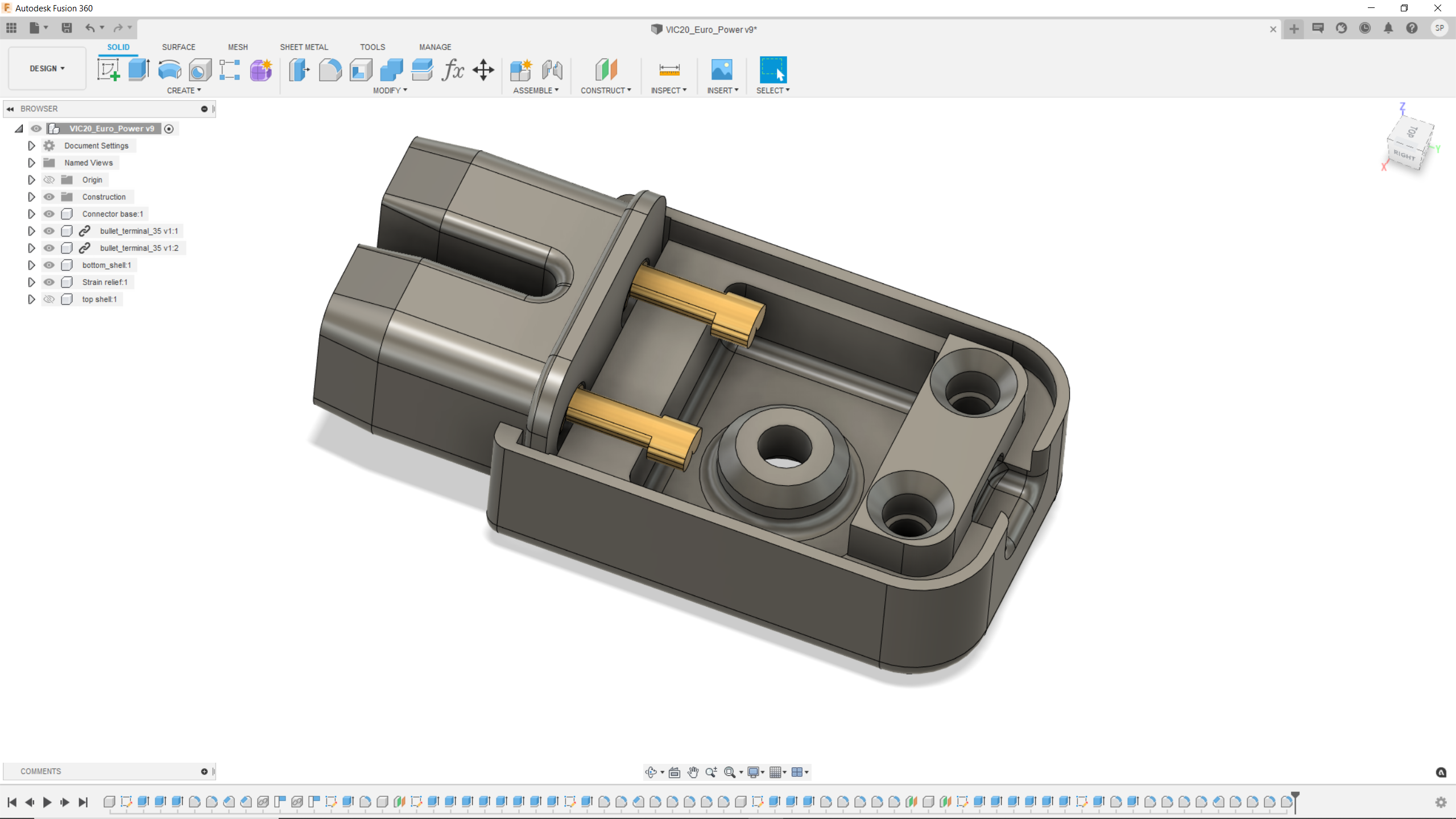

The connector was then drafted with Fusion 360. Top and bottom shell and the connector base were fitting well, the strain relief or rather the screws, that are holding down the strain relief were a tight fit, so the print was discarded and the construction was slightly changed (the position of the drills have been moved a bit).

Fusion 360 drawing of the VIC-20 Euro Power plug (top shell invisible)

Cross section of the connector

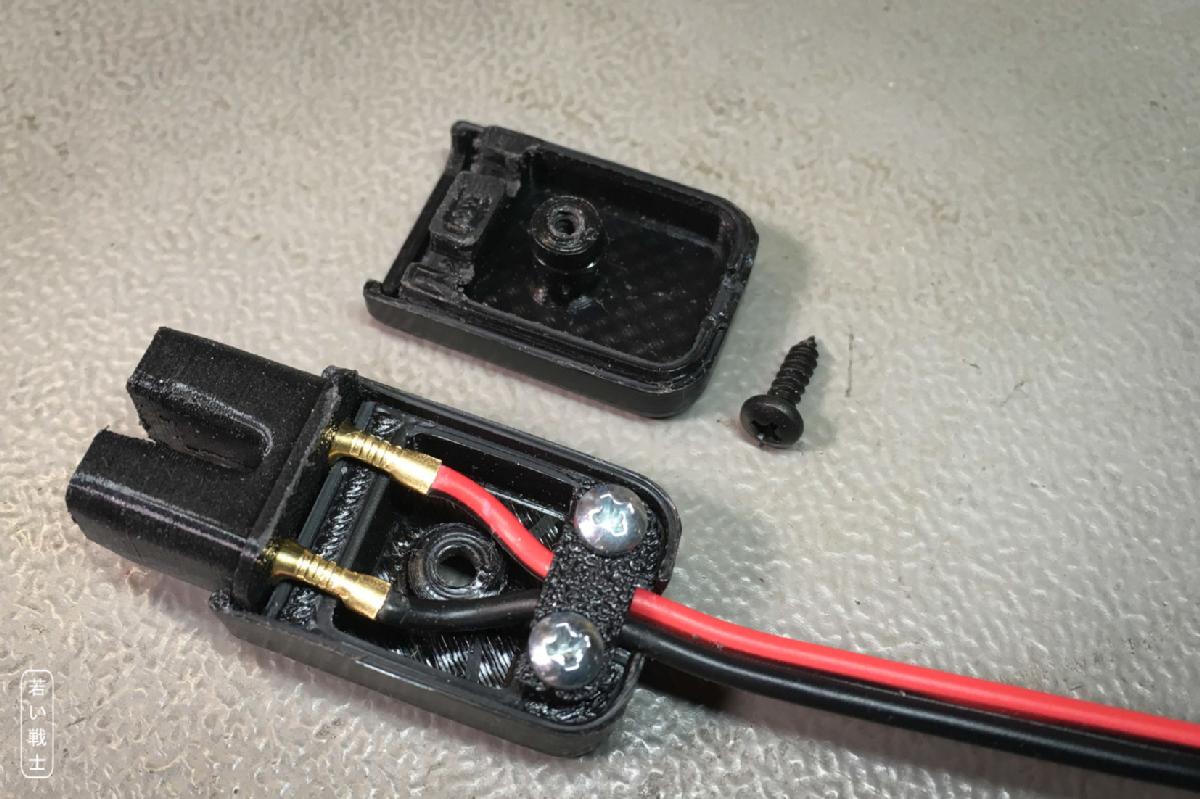

The printed parts

The parts were printed with Jet Black PLA Prusament. The recommended screws are DIN 7982 C2.9x6.5H (countersunk head screw for sheet metal - 2.9mm, 6.5mm long) or DIN 7981 C 2.9x6.5H screws like in the figure above. The screw that holds the top and bottom shell is a DIN 7981 C 2.9x9.5H (black).

Hand drill for drilling the holes to measure

Since 3D printed holes are usually under size, they have to be drilled to size. I use a hand tool for this purpose. It is probably not a good idea to do this this with an electric drill, but such a drill can be used as a drill bit holder. The 10mm deep crimp terminal compartment is drilled with a 4.2mm drill bit, like shown in the previous figure. The other side is drilled with a 3.5mm drill bit. Make sure, all shavings are removed.

The crimp terminals are crimped with a the IWISS SN-28B (the AWG 20-18 notch). The used power cable is a 0.75mm² (AWG20) twin wire.

Cimped terminals and tool.

Cable installed in the connector base and the bottom shell, strain relief clamps it down

Finished connector

The other side of the cable was soldered to a 7 pin DIN jack for testing.

Be aware, that a regular C64 power supply is not good enough to power a VIC-20. The original power supply is rated 3A. I have measured a current of 1.85A drawn be the VIC-20. For testing the cable was connectd to a custom made PSU (PolyPower 64), that is capable of 9VAC/3A.

Be aware, that a regular C64 power supply is not good enough to power a VIC-20. The original power supply is rated 3A. I have measured a current of 1.85A drawn be the VIC-20. For testing the cable was connectd to a custom made PSU (PolyPower 64), that is capable of 9VAC/3A.

Testing the VIC-20 Euro Power Plug

The tests resulted in discarding a couple more connector bases: The seating of the conenctors was not reliable. Jiggling the cable or pushing the connector have resulted in interrupting the supply voltage, which is definitely not desired. First, the base was shortened about 1.5mm, then the tolerances and shape of the base (the chamfer) were slightly modified to get a more stable fitting conector. Finally, all mechanical tests were passed and the replacement plug is considered to be reliable.

Lessons learned:

The crimp terminal might have to be squeezed slightly, so they are contacting the pins more closely. Also, the diameters of the two holes are important. The connector should not sit loose. Each connector needs to be tested for a reliable connection.

Find project data on thiniverse.com: https://www.thingiverse.com/thing:5261083