Electrostatic Discharge (And The Protection Against It)

ESD warning

What is ESD?

Many semiconductors are damaged and/or destroyed by electrostatic discharge every day and hobbyists/makers, who think, it has never happened to them, probably do so often!

Now, what is ESD? It stands for electrostatic discharge and it happens, when electrostatic charge gathered on a surface result in a sudden flow of electricity due to contact to a body with different charges (potential). Everybody knows such effects when touching a radiator or a door handle after walking around, getting out of the car or taking off a wool pullover. This discharged can be felt as a little electric shock, can be heard as a crackling sound or even be seen (in the dark) as a spark.

What is causing the electric charges? Mainly, the charges are produced by triboelectric effects (usually friction or separating charges by separating surfaces, that have been in contact before) and electric fields. Walking on a rug or rubbing a ballon on a sweater might also be something most people have experienced. This can build up charged that result in voltages of several 10kV.

These are the discharges, that you can perceive, the least perceivable discharge is about 2kV. Most electrostatic discharges stay way below that level. Even a discharge of 100V can damage your circuits! It usually does not destroy the semiconductors completely and put them out of function, so the circuits might still seem to work and even passes the end test. But they will be damaged, that means, they might fail after a short time or they might not reach the specified values anymore.

This is, why professional asdsembly houses put a lot of attention to ESD. The floors are conductive, tables and tools are grounded, which is regularly monitored and documented. The workers wear ESD shoes and coats, which is checked on a daily base. That is quite an effort, but a good investment. As a rule of thimb , a failure on an assembled PCB might cost 10 times the value of the failed component, in a completely assembled system, it is already 100 times the value and after delivery to the cutomer(s) is might even be 1000 times the value of the component. This does of course not apply on hobby electronics, but it also means lost time, while searching for the problem and of course less fun.

A customer in the early 2000s returned about 10% of a controller board, that I had developed. The boards were tested well after production (of course!). While visiting him, I have noticed, that he had absolutely no ESD protection in his production facility. He did not work with electronics a lot, so it was not required. After modifying the workspace a bit, the failure rate of the delivered boards decreased dramatically. The required equipment was not expensive, but obviously quite effective.

ESD problems can be prevented with a few simple things:

1. Use an ESD mat

2. Use an ESD wrist band

3. Use conductive tools, if possible

4. Ground all this properly

5. Do not touch electronic components before you are not properly discharged

There is a further option of ESD mats on the floor, which only makes sense, if ESD shoes and ESD chairs are used as well. IMHO a little bit over the top for a hobby lab. A wrist band is a proper substitute for that.

The grounding is not a direct grounding to PE. To prevent severe electric shocks, the mats and the wrist-band etc. is connectied to PE via a >1MOhm resistor.

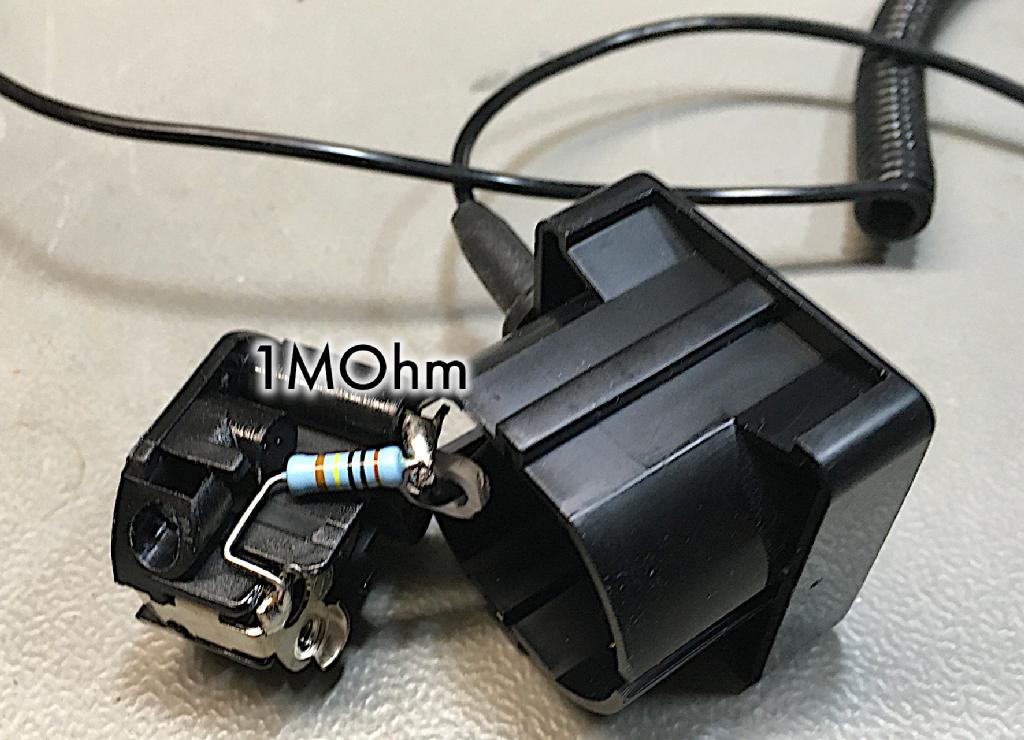

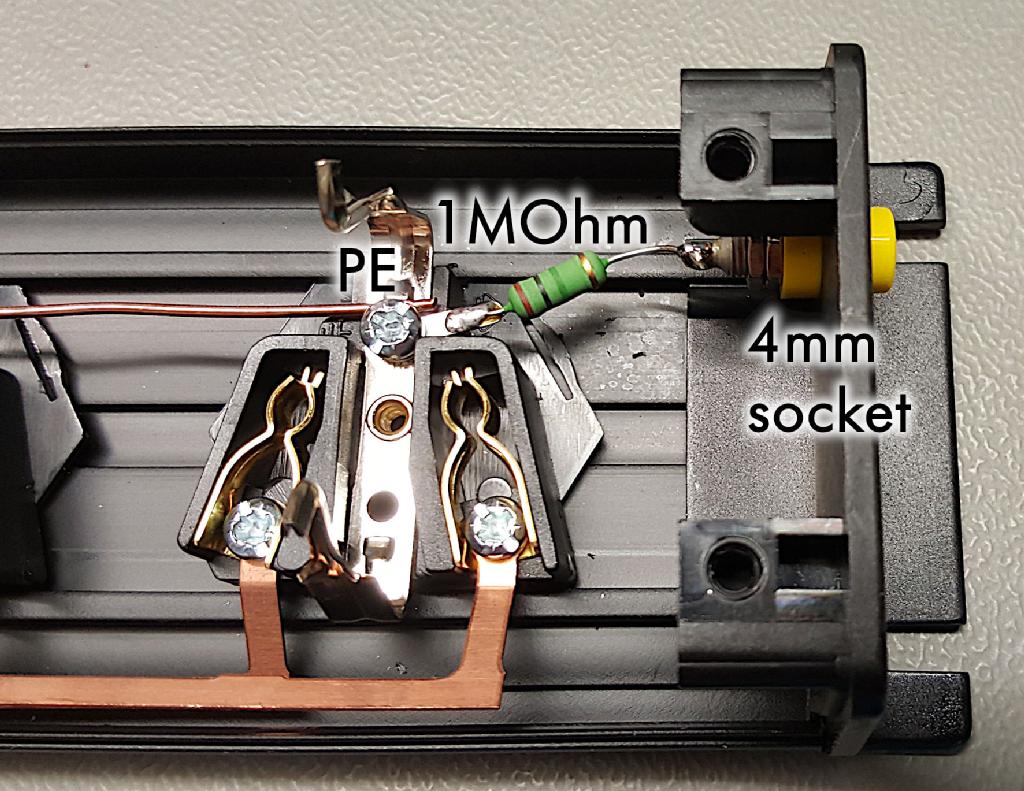

Grounding points for the electric outlet are a bit pricey, so it can be considered to hack a suitable multiple socket outlet and directly install a 1MOhm resistor and a 4mm lab socket.

A commercial grounding point (open)

Hacking a multiple socket outlet is not recommended, because if this is conducted in a not suitable way, it can result in leathal electric shocks. The following pictures and text is for educational purposes only.

The resistor in this commercially available grounding point can be discussed. A pulse voltage rating of 4kV or above might be a good idea. A resistor that fits this specification was not found. So it would be possible to use 4 250k resistors with a 1kV rating in series instead (those usually have a higher wattage, like 3W or 5W).

A hacked multiple socket outlet

It is very dangerous, if anything inside gets lose and can touch the hot end of the mains. This is, why I don't want to encourage anybody to do this modification.

Grounding point connected to an ESD mat (the grey mat below)

As an ESD mat, I recommend one with two 10mm snap fasteners. This is a standard for connecting grounding points and wrist-bands etc.

Some of my ESD equipment:

1. A grounding point

2. An ESD mat with a 10mm snap fastener

3. A wrist-band

4. A groundig wire with a 4mm plug

5. A grounding wire (as an interconnect between two ESD mats)

6. ESD shoes (my wife's)

7. A touch pad (equipment from the last millennium).

8. ESD brushes

9. ESD solder pump

So, cleaning your assembled PCBs with an old toothbrush is a really bad thing to do. Especially, when it is dry. Everything with moving parts is really bad, due to the charge separation, so an ESD solder pump is another things, that is recommended.

Many soldering stations have a ground socket, which should also be connected, if possible.

Symbol for ESD protecting materials

After production and handling comes storing and/or transport. It is as important to keep your electronic components or assemblies (as long as not built in an enclosure) as ESD safe as the handling was before.

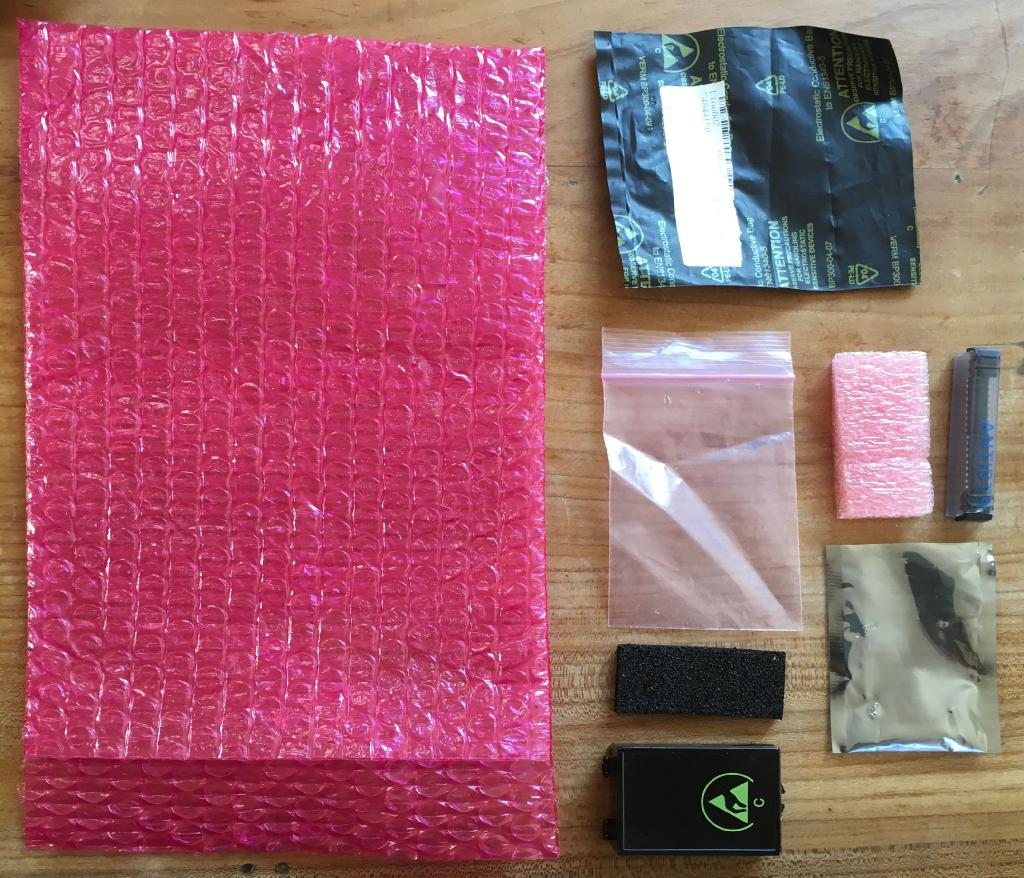

For this purpose, there is anti-static packing materials, such as (pink) bubble wrap, (zip lock) bags in light blue, pink, black or silver, IC rails, ESD safe boxes or anything with an ESD symbol on it (refer to the image above). This materials are not necesarily conductive, but anti-static.

ESD protecting materials

I have received a link with a cordless ESD wrist band. This is ridiculous!!! Please don't buy such a crap.