Rejuvenating The Conductive Rubber In a (Commodore) Keyboard

In August 2020 Jeff Birt from the Hey Birt! youtube channel came up with a video, showing how to rejuvenate the conductive rubber of (vintage computer) keyboards: https://youtu.be/n9gGz2n-sBU

I found this very interesting, especially, since I have seen other people destroying keyboards, while trying to clean the keyboard rubbers, that got high impedance, thus keys that don't work anymore.

Jeff found out, that it might be an oily substance, which contaminates the surface of the conductive rubber. This could be silicon oil, that is bleeding from the rubber over time. It was suggested to remove it with a mild caustic cleaner, so Jeff used some ammonia solution, in which he had soaked his keyboard plungers/conductive rubbers) for several days.

I found this very interesting, especially, since I have seen other people destroying keyboards, while trying to clean the keyboard rubbers, that got high impedance, thus keys that don't work anymore.

Jeff found out, that it might be an oily substance, which contaminates the surface of the conductive rubber. This could be silicon oil, that is bleeding from the rubber over time. It was suggested to remove it with a mild caustic cleaner, so Jeff used some ammonia solution, in which he had soaked his keyboard plungers/conductive rubbers) for several days.

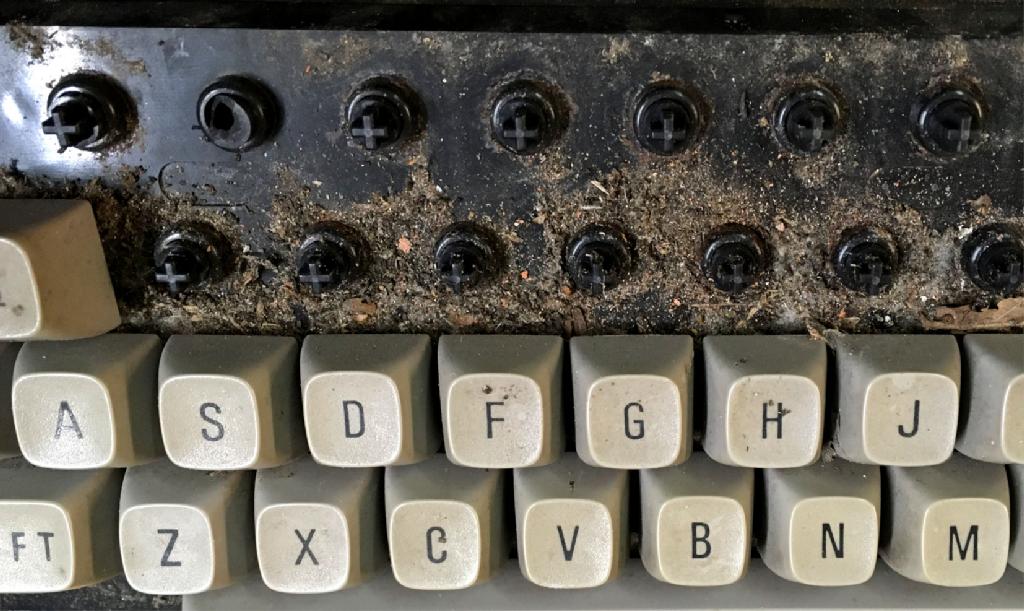

Filthy Commodore C16 keyboard

Since I have purchased a Commodore C16 with a really bad keyboard, I had enough material for my experiments on that topic. Since I did not want to use ammonia due to its smell, I considered trying a sodium hydroxide (NaOH) solution. First, I have selected some bad keyboard rubbers with the test fixture, that Jeff Birt has provided to me.

Jeff Birt's Test Fixture

The fixture consists of a gold-plated PCB, which is installed in a 3D printed keyboard plunger guide template. For testing, it is connected to a multimeter/ohm-meter. An impedance of less than a few 100 ohms is good. The majority of the plungers of the C16 keyboard had impedances of a couple of kohms or higher.

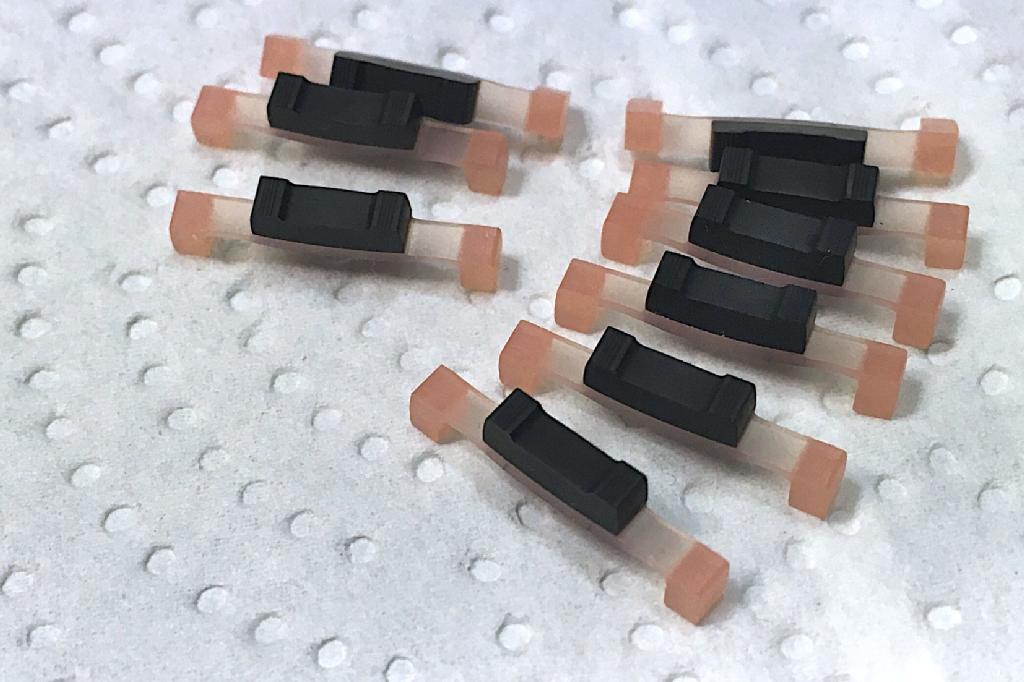

Conductive rubbers of a C16 keyboard

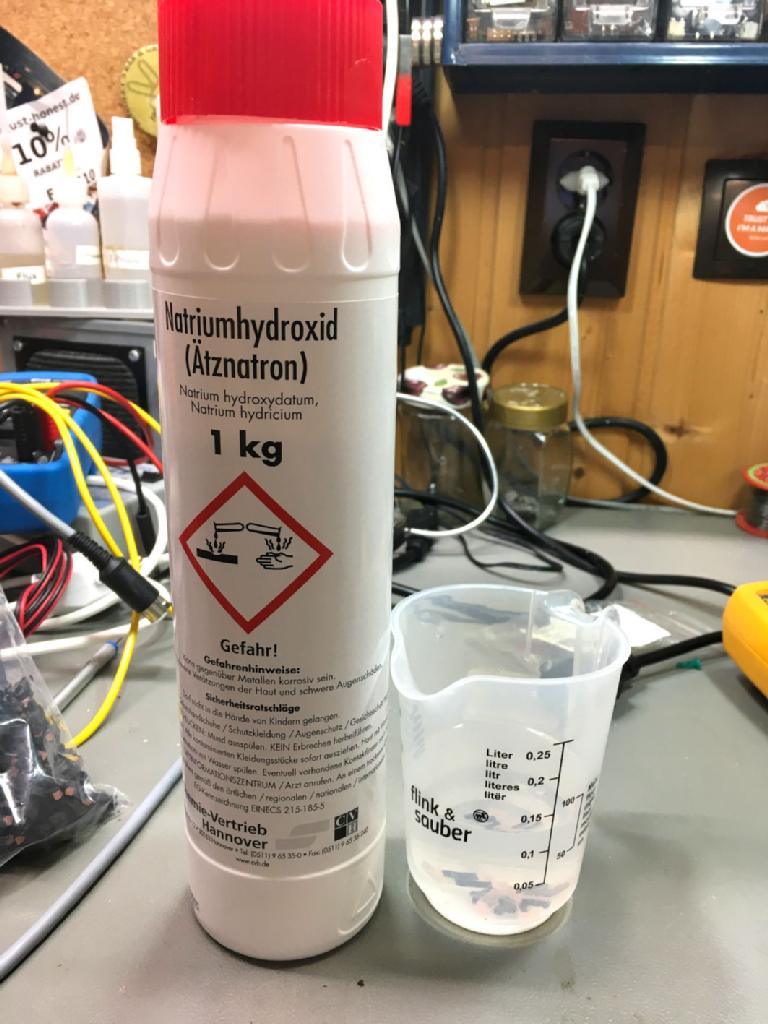

Soaking the conductive rubbers in a NaOH solution

The first attempt was a solution of 1 teaspoon of sodium hydroxide in 1/8 liter of demineralized water. A couple of 10-20kohm conductive rubbers were soak in this solution for about 24 hours. After this time, the conductive rubbers were removed and carefully rinsed with tap water and finally demineralized water. Then they were dried for four or five hours.

Compared to the original rubbers, the black part got really deep black with a matt surface. The kitchen paper, on which the rubbers were dried, had some black carbon traces and it looked like something had driven the carbon out of the rubber. Unfortunately, it was not so visibles on any of the pictures, that I took of the treated contact rubbers.

After installing them on a plunger, they were measured in the fixture, showing impedances of 60 to 80 ohms, which is totally fine.

The observations have then raised a couple of questions:

1. is a solution of baking soda suitable to achieve the same results?

2. is soaking the contact rubbers in pure water also producing good contact rubbers?

To answer these questions, a glass of water (1/8 liter) with 1 teaspoon of baking soda and another glass with pure demineralized water were prepared and the rubbers were soaked for 24 hours.

None of the conductive rubbers showed a significant change of its original impedance. So, pure water will not have any effect and a baking soda solution of this low concentration will not have any effect within 24 hours. A higher concentration over a longer time, might yield other results, though. This was not proved.

Subsequently, the still bad rubbers were soaked in the sodium hydroxide solution for 24 hours, which then had good results. The conductive rubbers had a resistance of around 70 ohms.

The next question was:

3. Do the rejuvenated conductive rubbers wear out early?

To answer this question, a contact rubber with an initial impedance of 70 ohms was installed on a plunger, which was then mounted in the C16 keyboard.

The long term stability test

The prepared key was actuated hardly for 10000 times, rather in a "gaming/pinball" style than in a "text processing" style. After some time, the key was disassembled and the impedance was measured.

The experiment shows, that the impedance was even getting better as the experiment progressed.

The concentration of the sodium hydroxide solution, that I have used, was probably higher than the 4% ammonia solution, that Jeff Birt has used in his experiment, which resulted in a suitable soaking time of 24 hours (not several days like the ammonia solution). He also did not notice any degradation of his rejuvenated keyboard rubbers over usage.

I want to thank Jeff for his brilliant idea and research, for providing me with the test fixture, for answering my questions and discussing my results.