1541-II Head Latch Cam

One of the old floppy disk drives (1541-II), that were part of a Commodore haul, had a locking lever, that was just hanging down. Obviously, it was a mechanical problem. The hope, that something just fell out, was little and when I opened the case, I have seen, that something was pretty damaged.

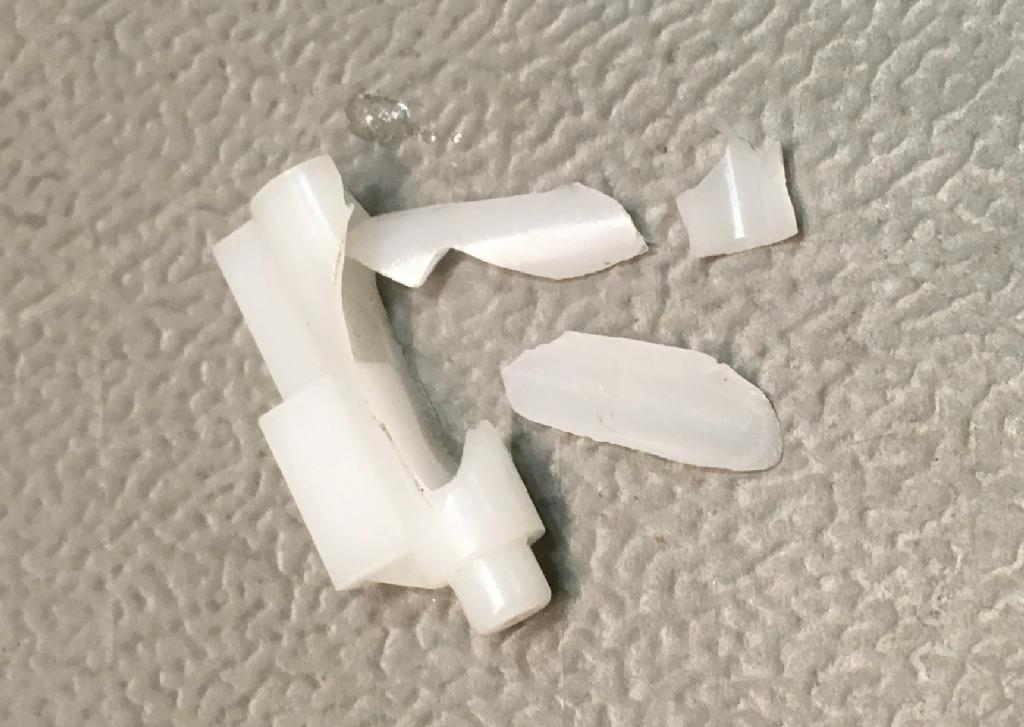

The broken 1541-II head latch cam

The plastic part is pressing down the read/write head fixture, which also lowers the centering/tractor disk, when locked. I did not believe, that glueing that part would last longer than 5 minutes. It is that typical sort of plastic, which just does not glue well. So, I have put the bits into a plastic bag and put is away... for a couple of months.

After I have finally bought a 3D printer and also learning to use Fusion 360 for 3D constructions and practicing a bit, I thought, I could construct and print a spare part. Actually, learning to use Fusion 360 (as my first 3D construction tool) was way less hard, than I have thought. I have used the PC to draw 2D things before and 3D constructions base on 2D drawings, which are then extruded to the 3rd dimension - ok, many more things can be done, but this is actually, what you need to do basic constructions. This kind of part and small boxes for your things are that kind of basic construction.

For measuring the part, I used an odrinary mechanic caliper. I am using my caliper almost on a daily base and I prefer the mechanic calipers over the electric ones. I have one, but whenever I want to use it, the battery is empty. I also don't really trust the calibration.

Here, the steps from nothing to a 3D model of the spare part are shown:

The step-by-step construction of the head latch cam

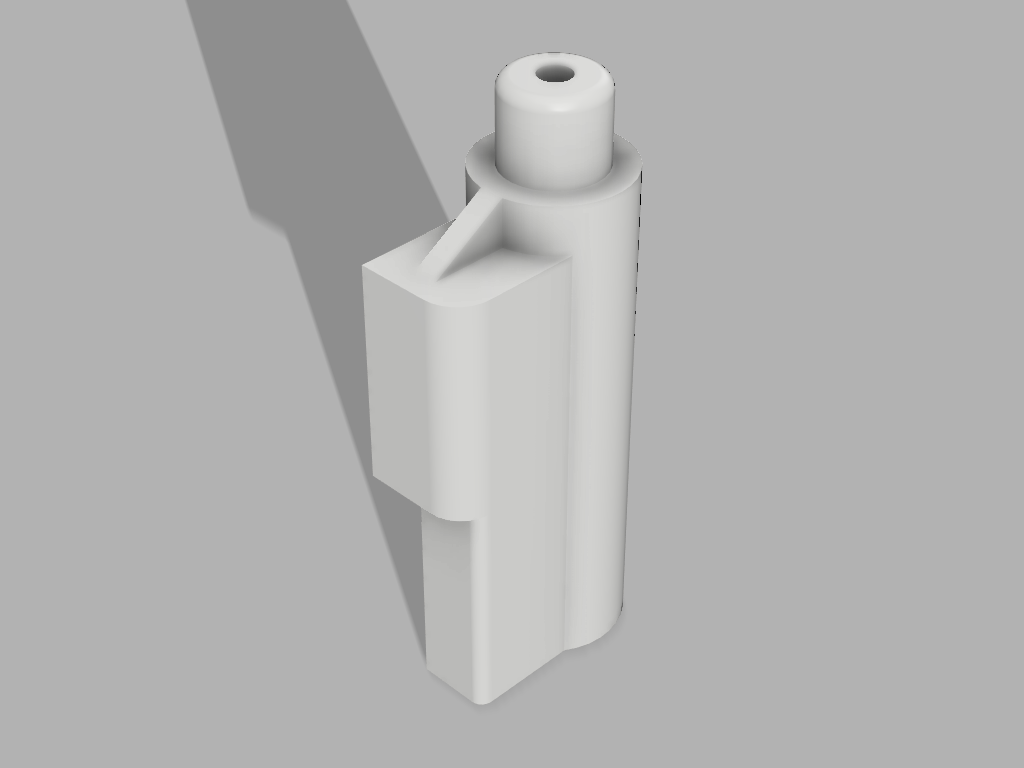

The rendered Fusion 360 construction

I have spent quite some time to figure out the best way to print it. It was important to have no supports inside the the drill, because that would make it hard to prepare the pinted part for being finished for mounting it on the metal rod.

The printed head latch cam after mounting it.

The resulting part works absolutely satisfying ever since.